.webp?width=300&name=VDLS850%20Production%20(1).webp)

Standard CNC Machining

We offer a wide variety of CNC standard machines including CNC vertical milling machines, horizontal machining centers, CNC lathes, and 5-Axis machining centers for your production solutions.

Standard CNC Machines

CNC Vertical Milling Machine Centers and More

Ingersoll CM Systems Provides a Complete Lineup of Standard CNC Machines

CNC machines provide levels of accuracy, efficiency and consistency that are impossible to achieve with manual processes. There are a variety of CNC machine types, each designed to accomplish specific tasks. At Ingersoll CM Systems, we feature the following standard CNC machines.

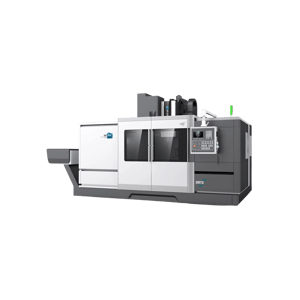

Vertical CNC Machining Centers

Vertical machining centers have vertically-oriented spindles that approach a work table-mounted workpiece from above. Vertical machine centers are outfitted with a tool magazine system. The open visibility of vertical machining centers makes them better for larger parts. VMCs are also ideal for easier, less complex jobs that require lower quantities. Vertical Machining Centers provide the following capabilities:

- Facing

- Centering

- Milling

- Drilling, Tapping

5-Axis Vertical CNC Machines

A 5-Axis CNC machine incorporates A and B rotary axes along with the X, Y, and Z linear axes to allow the cutting tool or part to simultaneously move in 5 directions. 5-Axis machines can perform:

- Facing

- Centering

- Milling

- Drilling, Tapping

Benefits of 5-Axis include:

- 5-Axis machining gives you the ability to produce parts with fewer setups. This leads to increased efficiency, decreased lead times, and increased accuracy.

- 5-Axis allows for shorter tools which reduces chatter and improves surface finish.

- 5-Axis allows you to create complex parts that could not be created with standard 3-Axis machines.

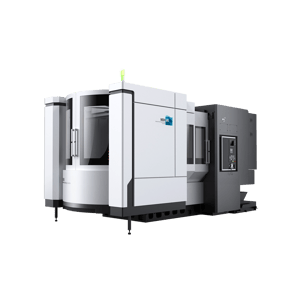

Horizontal CNC Machining Centers

Horizontal milling machines cut faster than vertical machines. Debris can be removed more quickly from horizontal machines. Because they are faster and more precise, horizontal machines are perfect for large production runs.

Horizontal Machining Centers provide the following capabilities:

- Facing

- Boring

- Milling

- Drilling

- Tapping

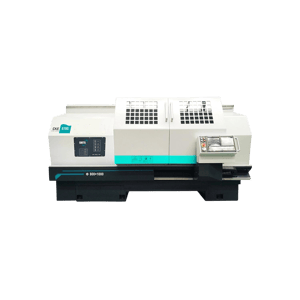

Flat Bed CNC Lathes

The stability of flatbed lathes make them ideal for heavy turning operations. Flatbed lathes are used for operations such as tapers and conical feature turning, grooving, cut-off, chamfering, and also drilling and reaming. Ingersoll CM Systems offers two types of flat bed lathes.

- Flat Bed CNC Lathe Gear Box Spindle Series

- Flat Bed CNC Lathe CKA-M Series

Slant Bed CNC Lathes

Slant bed lathes provide a 45-degree slant direction. Compared to flat bed lathes, slant bed lathes accept larger parts within the same footprint. Slant bed CNC lathes allow for flexible configurations that provide the following capabilities

- Turning

- Boring

- Threading

- Milling (Live Tooling)

Ingersoll CM Systems offers three types of slant bed lathes:

- CLS series

- DL-M

- DT series

Here's Why to Choose Ingersoll CM Systems for Standard CNC Machines

We are a full-service machine tool company offering everything from machine concept and design to field installation and service. We apply our 50 years of custom machine design and integration to your manufacturing challenge.

WE ARE KNOWLEDGEABLE

We know the intricacies of CNC machines and machining processes of many leading CNC brands.

WE ARE TRUSTED

Clients keep coming back to us. We work hard to earn our client's trust.

WE ARE EXPERIENCED

We have over 50 years of machine design experience. In addition to standard CNC machines, we also provide turn-key service to slash your commissioning times and let you focus on what you do best.

WE ARE BASED IN THE USA

From our Midwest home, we serve companies across the world.

Here’s What Ingersoll CM Systems Customers Say

We Provide Custom CNC Machines to the World's Leading Manufacturers

Ingersoll CM Systems is a CNC partner to OEM, Tier 1 and Tier 2 suppliers in a wide range of industries.

Need a Reliable CNC Machine? Turn to Us as Your CNC Solution.

Your production is too important to trust to just anyone. Contact us today to learn how we can help you.